Milling, Shaping, Sculpting and Modelling

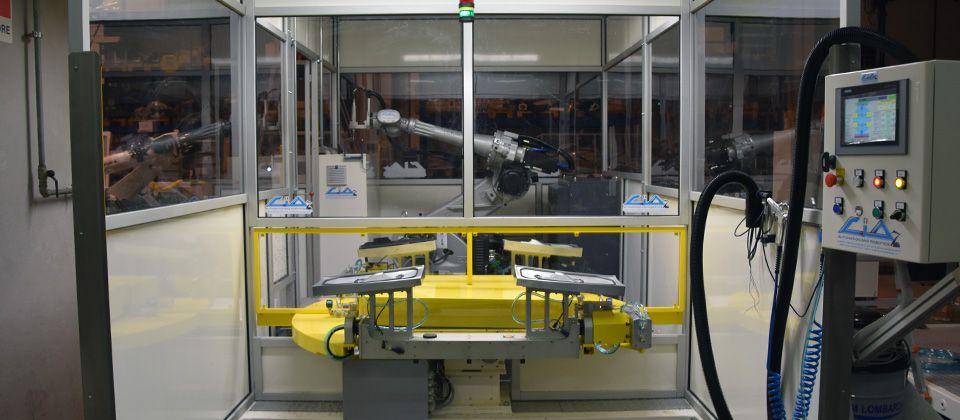

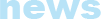

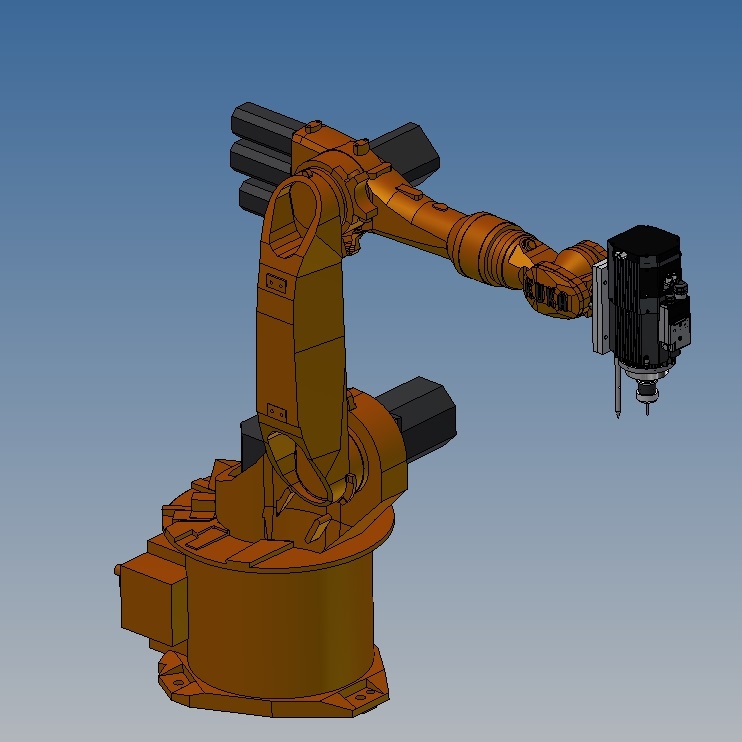

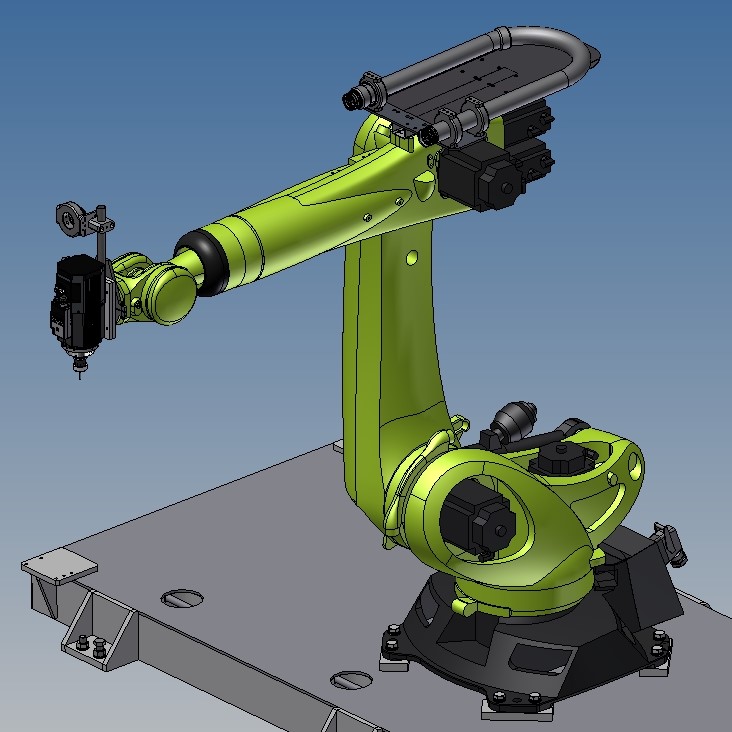

CIA Automation and Robotics' long experience in the field of automation, and the know-how it has acquired, enable robotised milling, shaping, sculpting and modeling units to be designed and produced for working with marble, stone, glass, wood, plastic, metals and compound materials.

CIA Automation and Robotics equips its own robots with spindles carefully chosen from the range of products of the most important manufacturers after analyzing the specifics of the work to be carried out.

Automation necessary to meet these requirements can be added to standard CIA Automation and Robotics robotised units.

CAD-CAM software turns designs into shapes and surfaces for robotic language. Objects, and indeed people, can be scanned using 3D laser systems .

CIA Automation and Robotics robotised units can also be used for squaring and working on marble and stone slabs.

|

|

SMALL |

MEDIUM |

LARGE |

|

|

|

|

|

|

Materials |

Wood-plastic-composite materials-marble-granite-stone-glass |

Wood-plastic-composite materials-marble-granite-stone-glass |

Wood-plastic-composite materials-marble-granite-stone-glass |

|

Robot brand |

KUKA – ABB – COMAU STAUBLI |

KUKA – ABB – COMAU STAUBLI |

KUKA – ABB – COMAU |

|

Robot payload |

10 Kg – 20 Kg |

60 Kg – 210 Kg |

400 Kg – 500 Kg |

|

Work area |

1400mm–1600 mm |

2000 mm – 3000 mm |

2800 mm – 3300 mm |

|

Maximum workpiece size |

1000 mm X 1000 mm H 1500 mm |

2000 mm X 2000 mm H 1500 mm |

2500 mm X 2500 mm H 2500 mm |

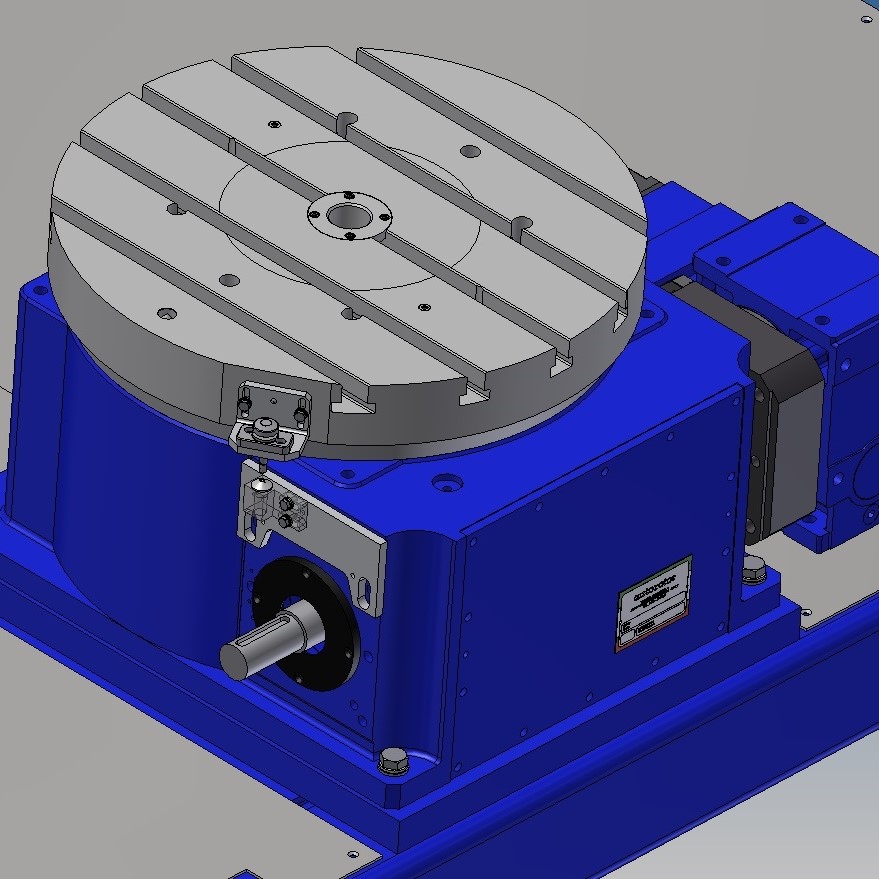

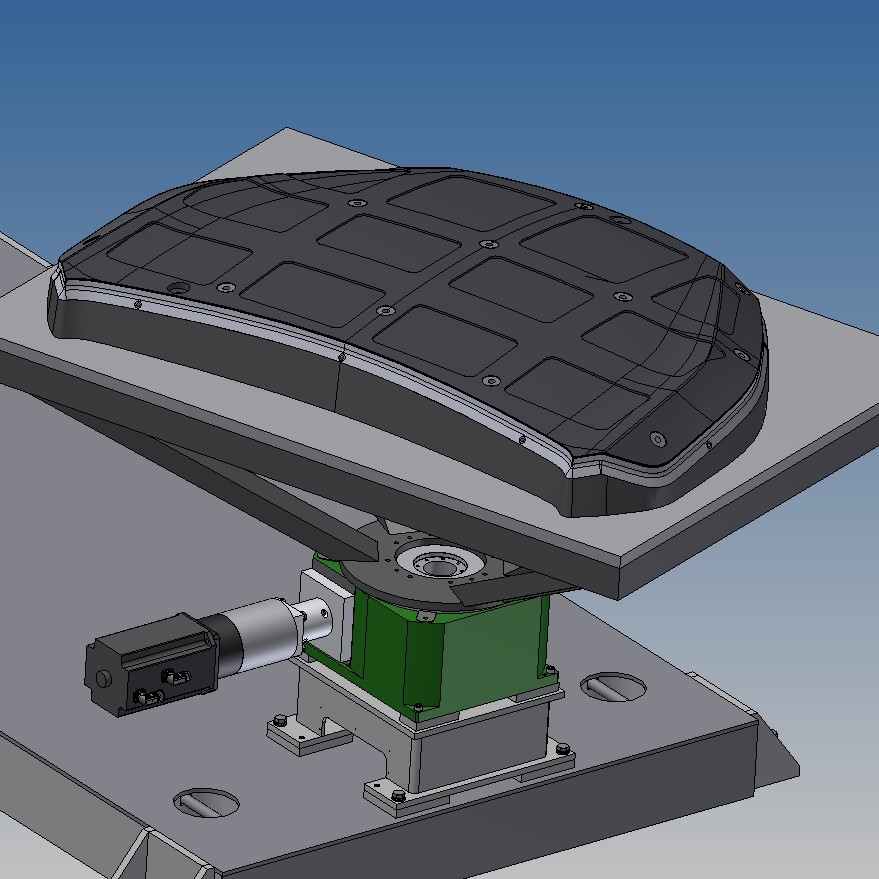

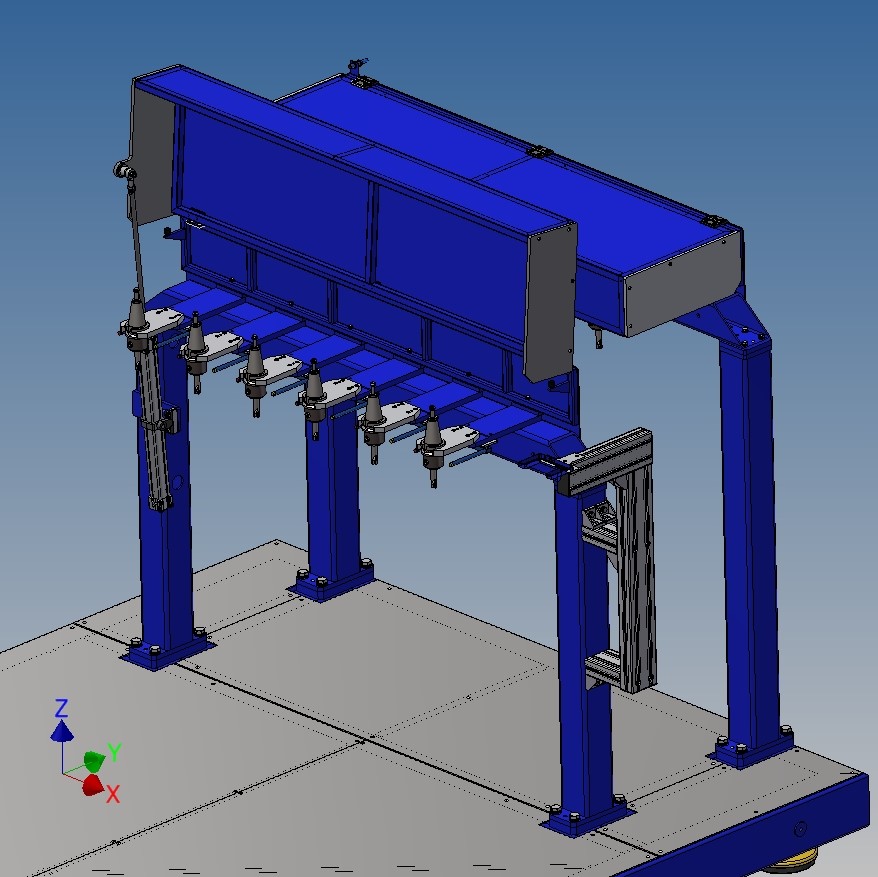

Rotating table

Rotating table with load capacity from 200kg to 30,000kg

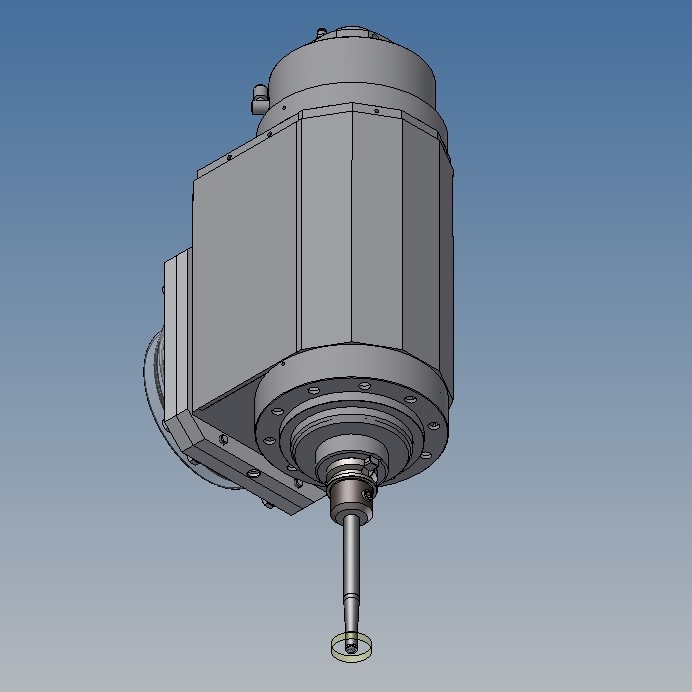

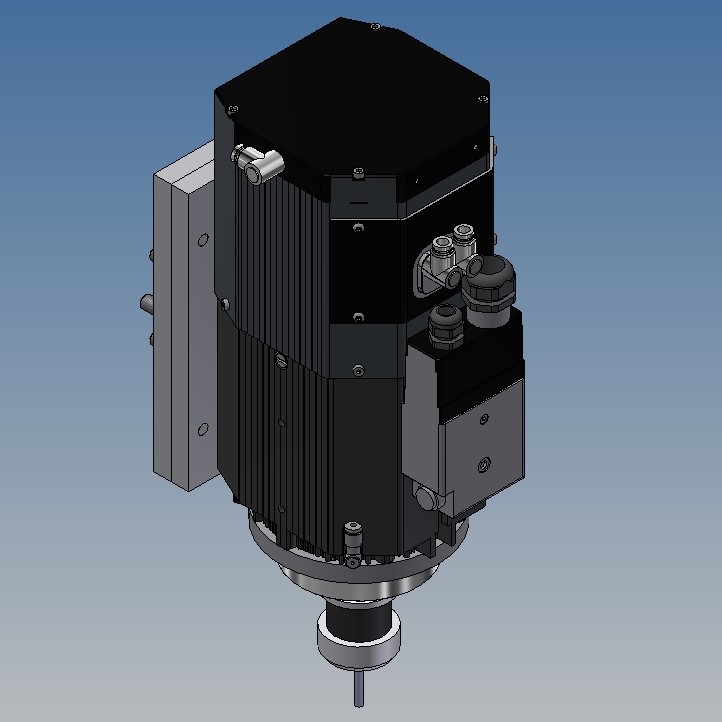

Electric spindles

Electric spindles with power up to 35kW, automatic hook-up and unhooking, liquid cooling and perforated stainless steel beam to apply cooling fluid to tools.

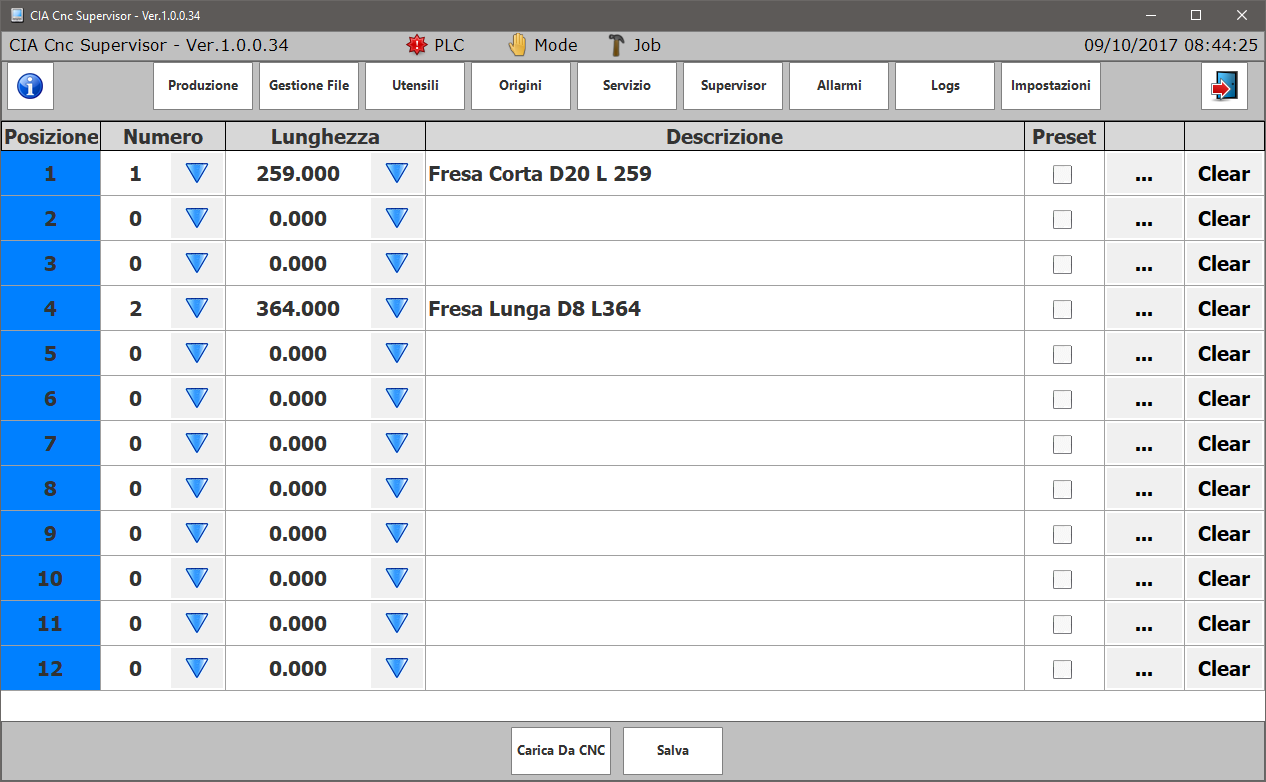

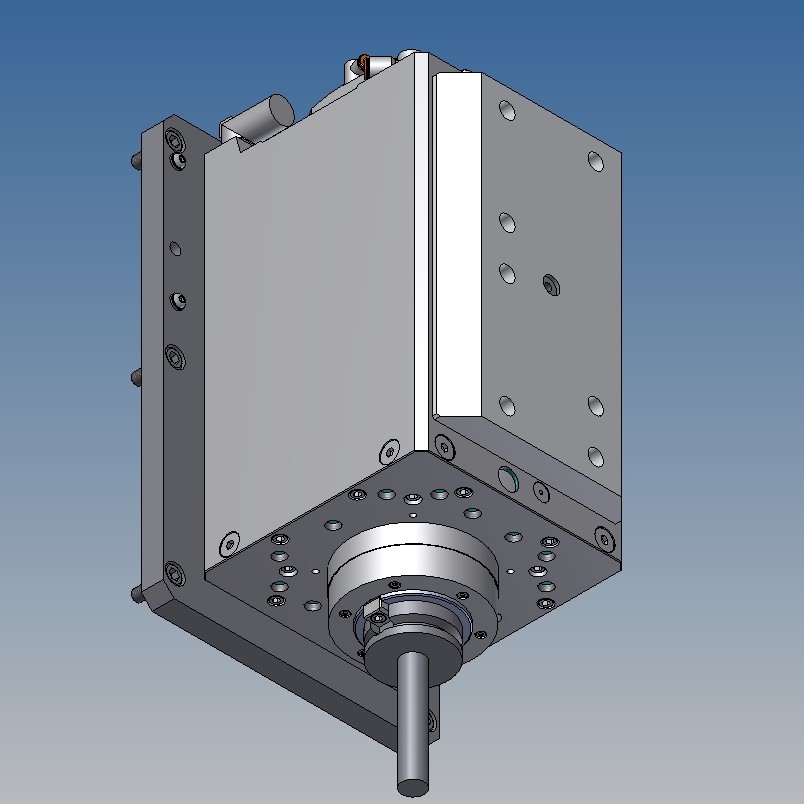

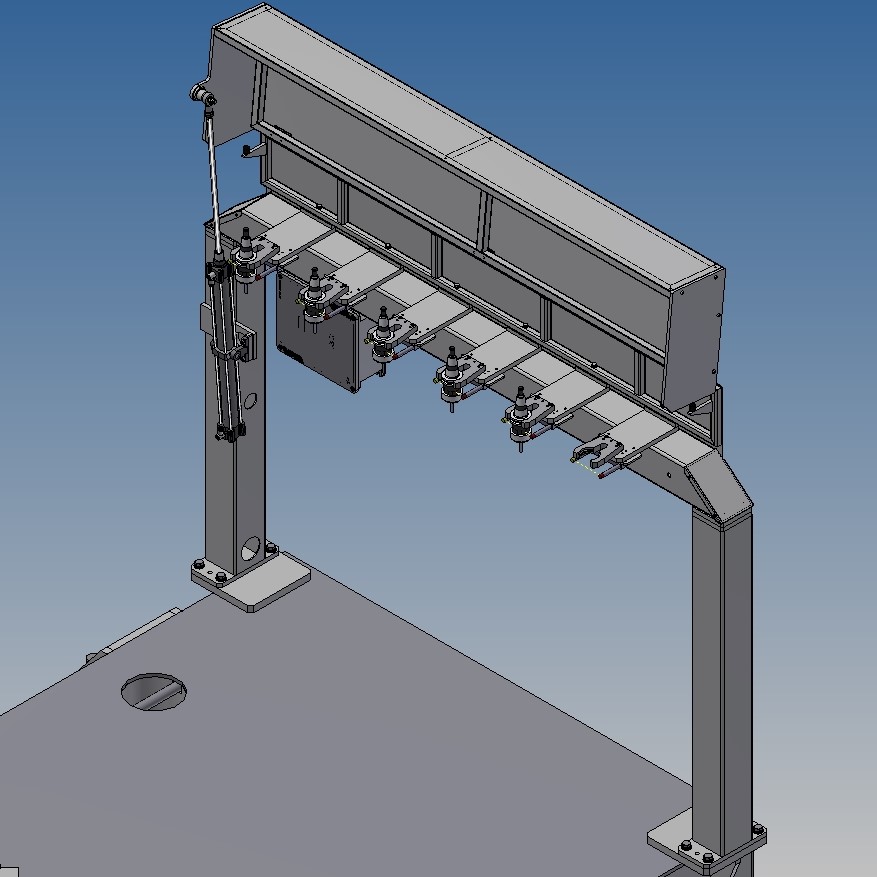

Tool storage

Tool storage able to hold from 6 to 20 tools, equipped with tool presence sensors and mill integrity control system. The warehouse also has a feeler unit for tool presetting.

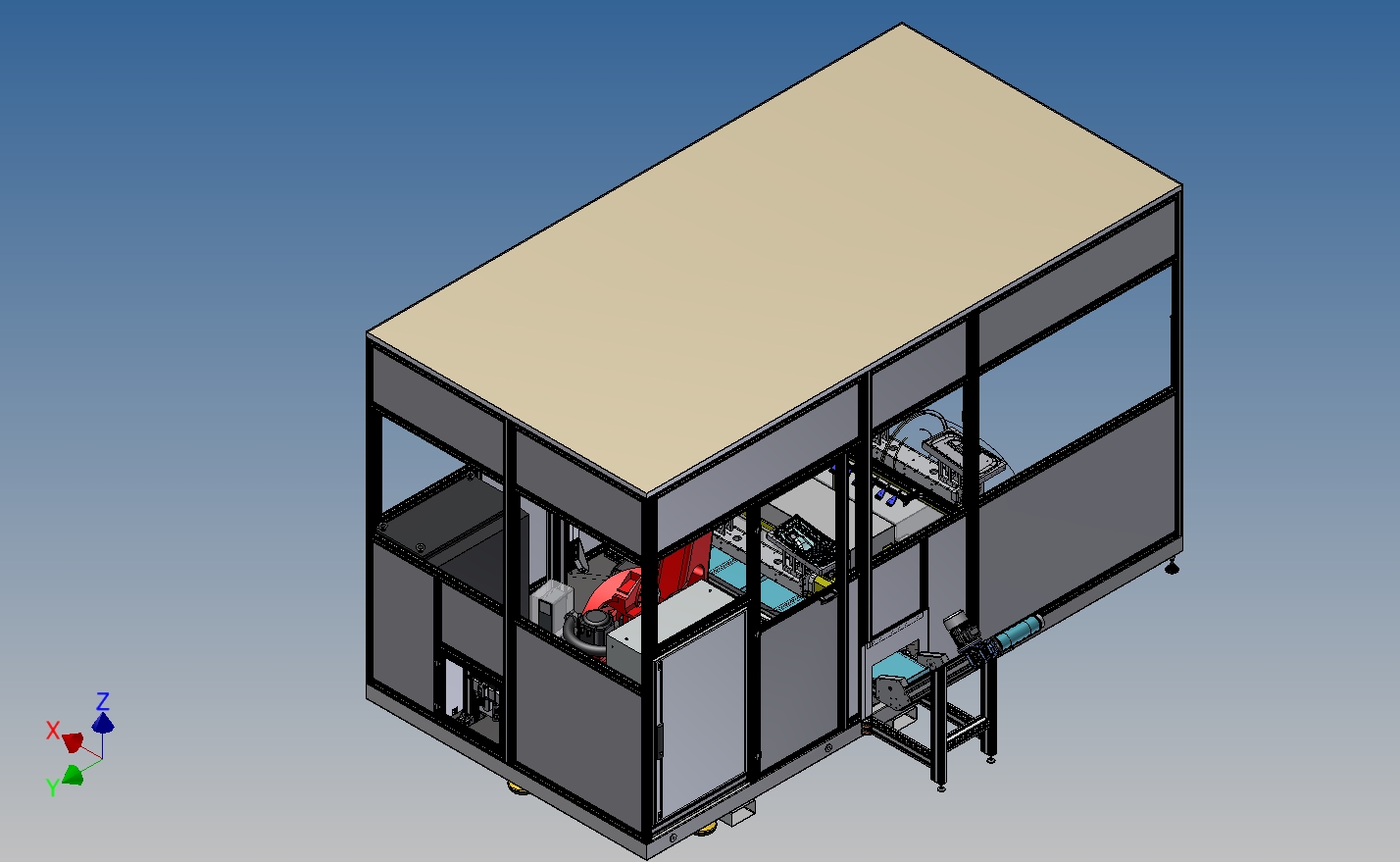

Unit protection cabin

Unit protection cabin with swing door access or safety photoelectric barrier.

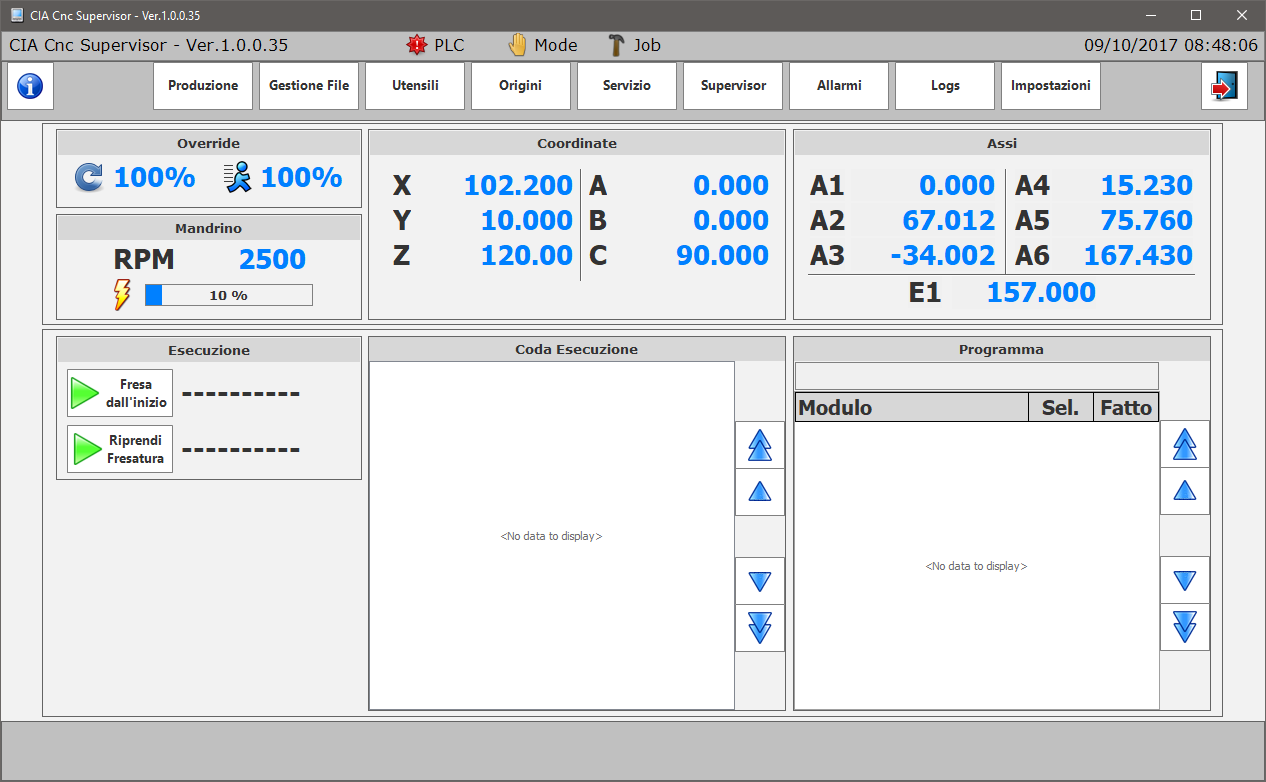

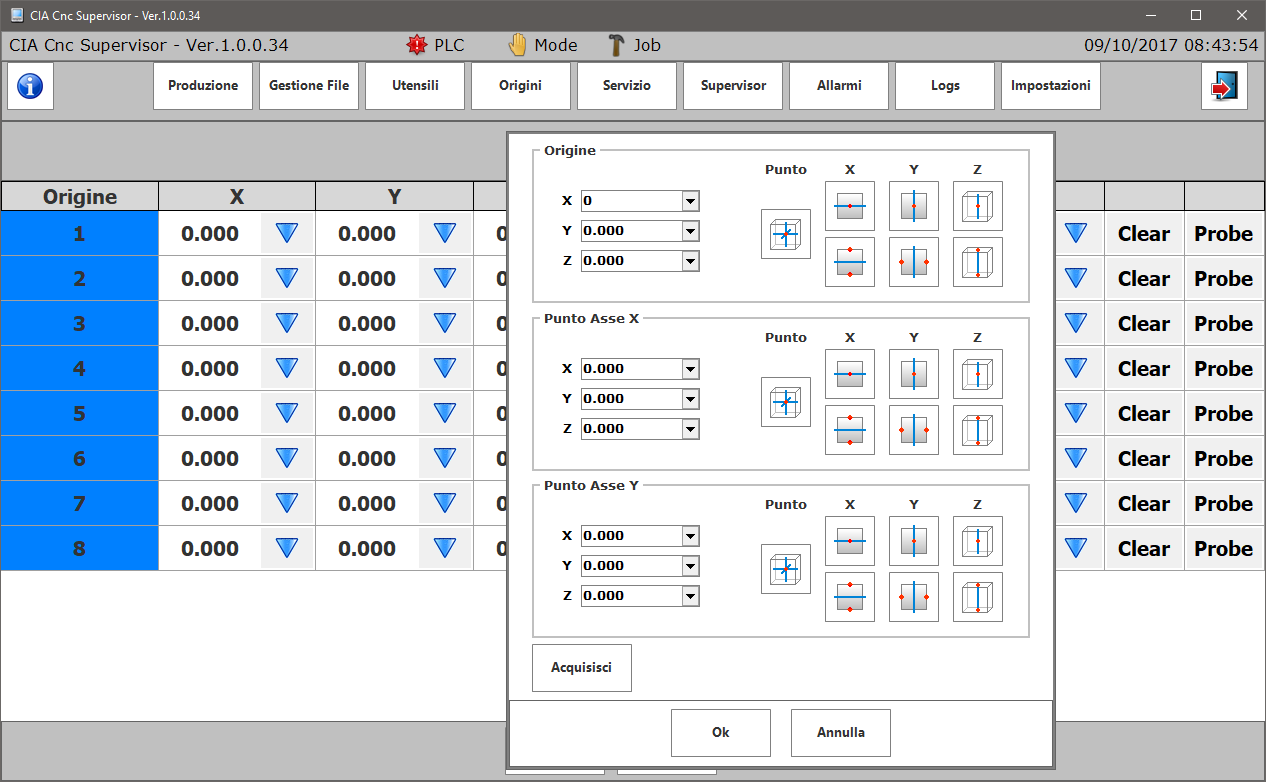

CIA CNC SUPERVISOR

CIA CNC SV is a robotised unit control panel developed by CIA Automation and Robotics which enables an operator to keep the state of the robot under control, upload/download work programs, set parameters, increase and reduce the robot's speed and that of tool rotation.